Cool Room & Freezer Windows: Single vs Double Glazing, Heated Glass, and Condensation ControlWindows in cool rooms and freezers are often underestimated. Get them wrong and you’ll see condensation, dripping water, fogging, mold around frames, hygiene issues, and energy losses. Get them right and you’ll achieve clear visibility, better thermal performance, and long-term compliance—without unnecessary upgrades. At TotalTrack, we design cold rooms and freezer facilities where windows perform in real operating conditions: temperature differentials, humidity loads, washdown regimes, and frequent door openings. |

|

|

|

Why cool room windows fog and dripCondensation is driven by dew point, not just cold temperature. When warm, moist air contacts a cold surface (like a window), water vapour condenses if the surface temperature is below the dew point. In practical terms, this means:

|

|

Single vs double glazing in cold roomsSingle glazing (generally not recommended)Single glazing has poor insulation and commonly causes condensation. Typical outcomes:

Where single glazing might be acceptable |

|

|

|

Double glazing (standard choice for cool rooms)For most cool rooms (including +4°C rooms), double glazing is the minimum recommended option. Benefits:

Typical specification direction

|

|

Do cool room windows need to be heated?For cool rooms around +4°C: usually noIn most +4°C cool rooms, heated glazing is not required if the window is properly designed, detailed and located. Instead, condensation is usually managed through:

|

|

|

|

When heated glass may be justified (even at +4°C)Heated glazing becomes a practical solution where condensation cannot be tolerated or where environmental conditions are harsh. You may justify heated glass when:

Heated glass is often installed as an anti-condensation measure—it gently warms the surface to keep it above dew point. |

|

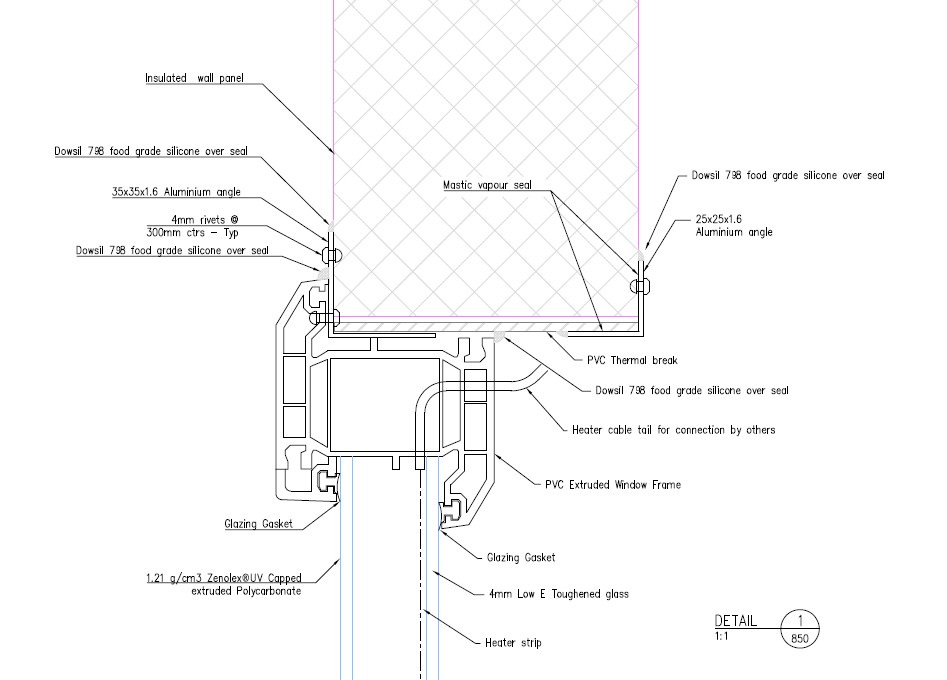

Freezer windows: different rules applyFreezers (for example −18°C) create a larger temperature differential and frequently require a higher-spec window design. Typical freezer window requirements:

|

|

|

|

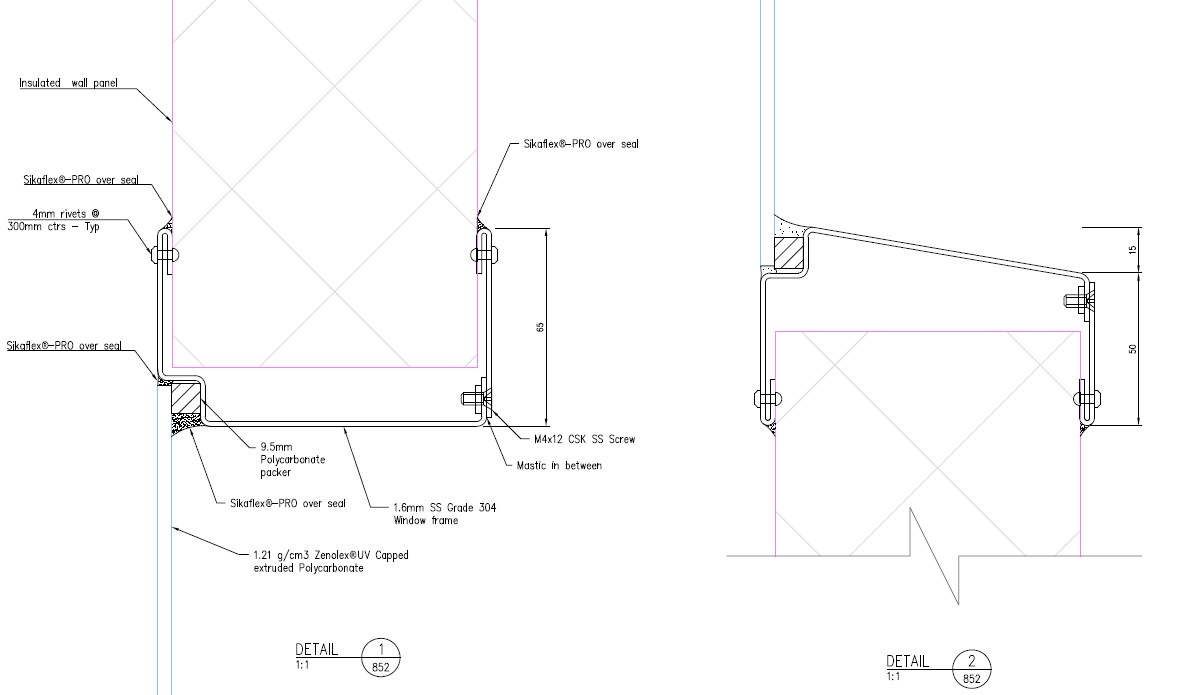

The part most people miss: frames, vapour seals, and thermal bridgesEven the best glass can fail if detailing is poor. TotalTrack designs windows as a complete assembly:

|

|

TotalTrack design guidance (simple rule-of-thumb)Cool rooms (~+4°C)

High-humidity cool rooms / washdown zones

Freezers (e.g., −18°C)

|

|

|

|

FAQWill a cool room window always fog at +4°C?Not always. Fogging depends on the humidity and dew point of the air contacting the window. Double glazing plus good detailing can reduce or eliminate fogging in many environments. Can I use standard house windows in a cool room?Usually no. Residential windows generally aren’t designed for cold-room vapour management, thermal bridging control, or hygienic detailing. Cold-room windows should be specified as part of the insulated envelope. Is heated glass expensive to run?Heated glass adds energy use, but it can prevent ongoing condensation problems that create higher costs through maintenance, hygiene risk, and operational disruption. Whether it’s worthwhile depends on humidity load and traffic. What’s more important: the glass or the frame?Both matter, but frames and vapour sealing are often the deciding factor. A thermally broken, vapour-tight installation can outperform “better glass” installed poorly. |